LEAN / Six Sigma - Healthcare

Improving Patient Outcomes by introducing Lean Thinking Principles

✔︎ In Person

Lean / Six Sigma is a unified approach to achieving improved performance, which, when correctly deployed, will drive continuous improvement, or even dramatic step changes in performance, and will be a major enabler in achieving the goal of becoming an “Outcome Focussed Organisation”.

Skills you’ll gain:

✔︎ Management ✔︎ Continuous Improvement ✔︎ Strategic Planning

-

- Heightened awareness of the 5 Lean principles and their application.

- Deeper understanding of Continuous Improvement concepts, including Kaizen.

- Customer and Stakeholder Identification

- Learning how to map the Customer Value Stream.

- Distinguishing between Value Add and Non Value Add processes.

- Understanding customer perceptions of their service.

- Learning how to obtain “The Voice of the Customer”.

- Greater understanding of the impacts of change on people and processes.

- Knowledge and appreciation of performance management.

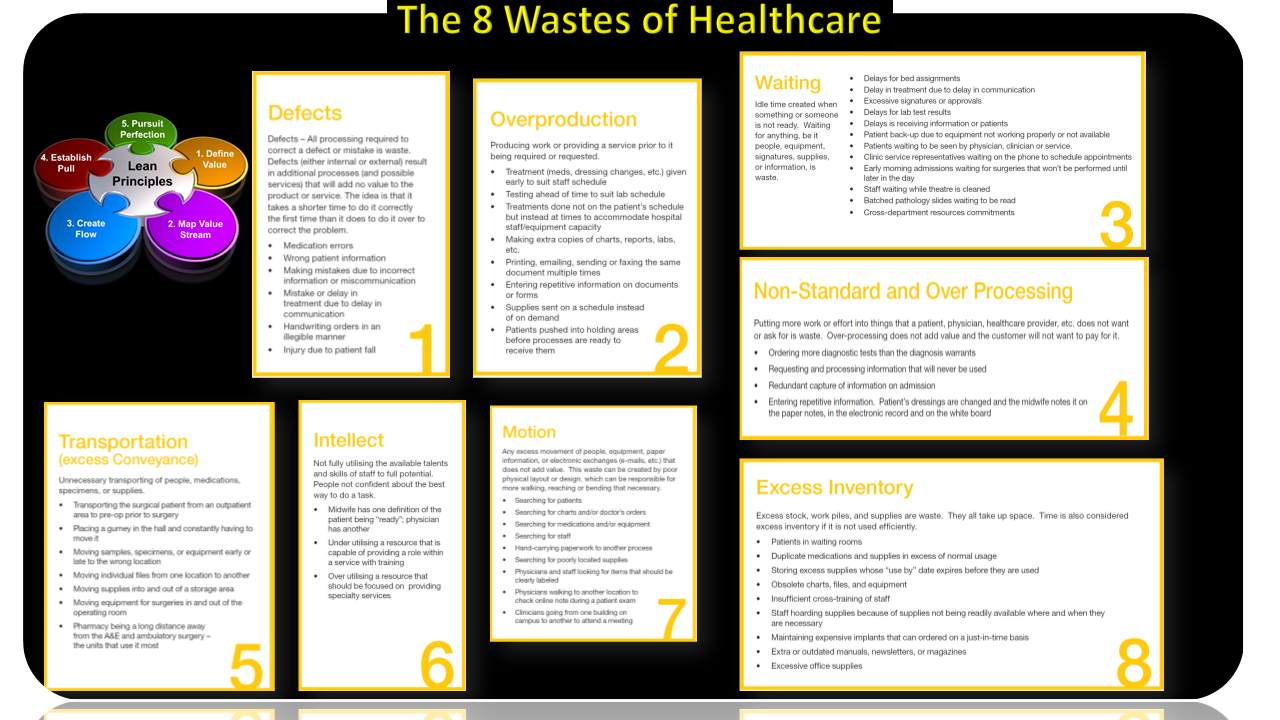

- Identifying the 7 areas of waste.

- Learning how to maximize efficiency by eliminating waste.

- Applying Solutions Focused Thinking, De Bono’s Thinking Hats, and Root Cause analysis using Ishikawa templates.

- Creating benchmarks and improvement targets.

- Integrating measurements into processes.

- Understanding individual reactions to change.

- Choosing winning behaviors and attitudes for change.

- Importance of creating a high-performance Lean project team.

- Visualizing a “Future State” using Appreciative Inquiry and Disney Creative Strategies.

- Process mapping from current state to future state.

- Enhancing team working awareness through participation in experiential activities.

- Creating a common language with support staff when discussing Lean projects.

PART 1: What is LEAN?

PART 2: Foundations of Success

PART 3: Enabling Building Blocks

PART 4: Improvement Tools and Techniques

The cost will be £975 + VAT for 1 days of training, for up to 12 delegates – including all preparations, trainer’s expenses, and materials.

This course also exists as a 2-day offer, extending the depth covered and costing £1,940.

Improving Patient Outcomes whilst Reducing Costs with LEAN Thinking

Click here to download an overview of Lean Thinking in the NHS

What is Lean Thinking?

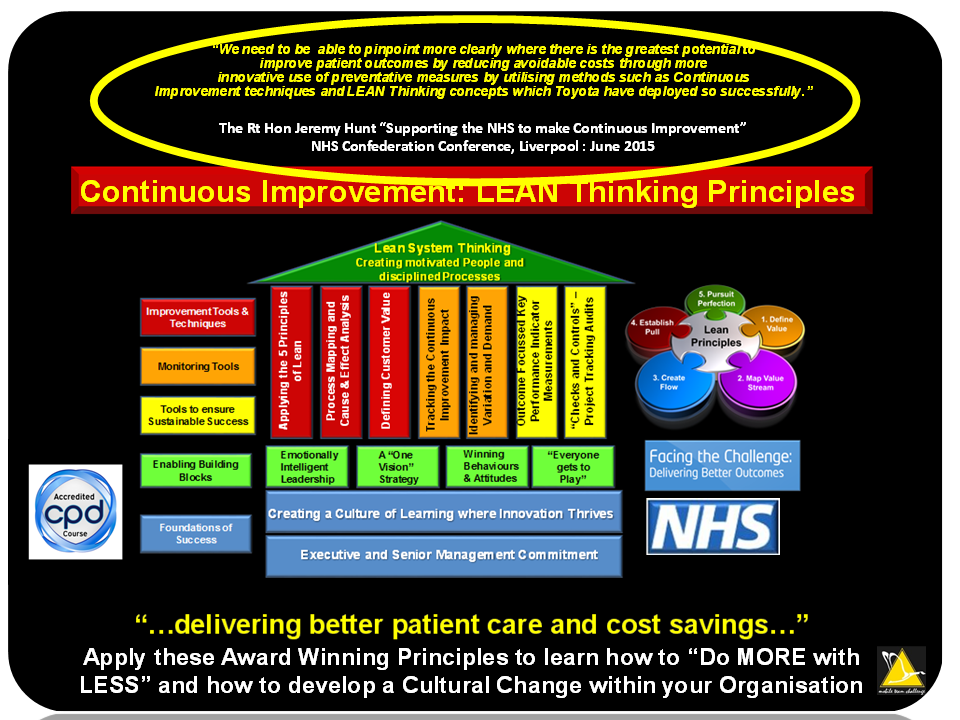

At the NHS Confederation Conference in Liverpool in June 2015, the Right Honourable Jeremy Hunt MP and Secretary for Health said:

“We need to be able to pinpoint more clearly where there is the greatest potential to improve patient outcomes by reducing avoidable costs through more innovative use of preventative measures by utilising methods such as Continuous Improvement techniques and LEAN Thinking concepts which Toyota have deployed so successfully.”

So…what IS Lean Thinking and HOW can it help the NHS in their cultural change programmes?

Lean is a unified approach to achieving improved performance, which, when correctly deployed, will drive continuous improvement, or even dramatic step changes in performance, and will be a major enabler in achieving the goal of becoming an “Outcome Focussed Organisation”.

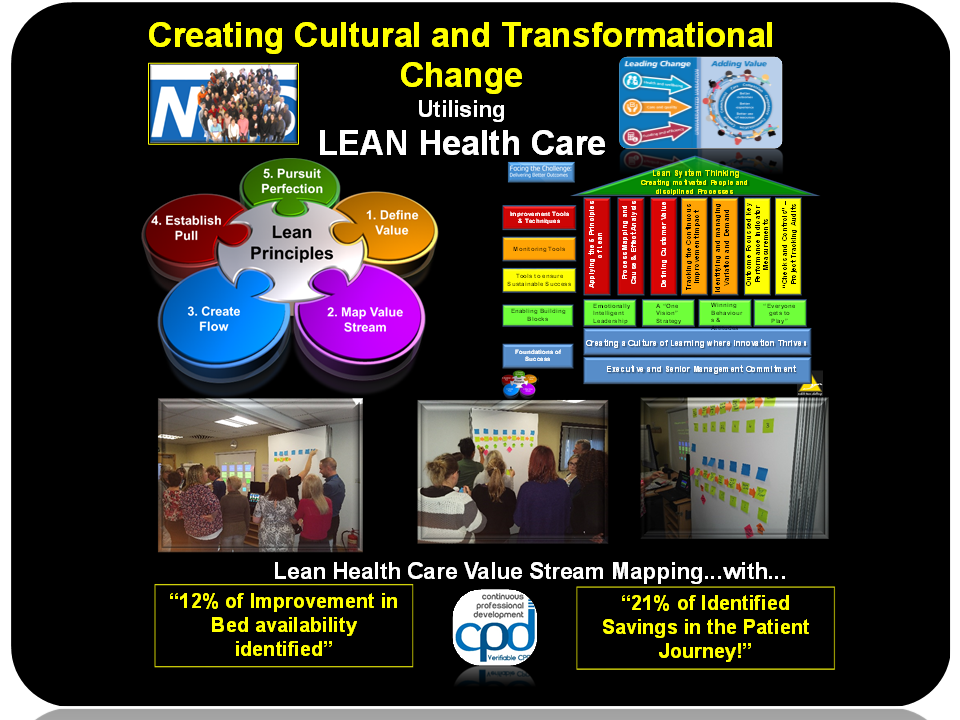

From integrating quick pace transformational change to maximising customer value whilst minimising waste, the Lean Continuous Improvement principles create the Winning Behaviours and Attitudes across the “people and processes” across any organisation.

“We must become far more disciplined in managing project programmes with less dependency upon a few key individuals and more systematic and rigorous approach to project and programme delivery across the whole organisation” – is a strategic statement of intent which we hear on a daily basis from many organisations and the implementation and practice of the transforming 5 Principles of Lean and Continuous Improvement are the perfect vehicle required to achieve this desire.

In the current political and economic climate there is a focus on public services to do more for less, i.e. to be more efficient. NHS departments and local authorities are in the process of working on the detail of how budget cuts will be implemented. An important methodology at the disposal of public sector managers is Lean, which can deliver many benefits.

The approach can be applied in many situations and is equally relevant within the private and public sectors. Many major organisations have already adopted the methodology of Lean and they are experiencing remarkable improvements as a result.

Using a rigorous data based approach, Lean encompasses an extremely wide and comprehensive toolkit as well as a structured methodology for deploying these tools, to increase customer satisfaction, drive out errors and waste, reduce cycle times, reduce costs and improve delivery.

The Graphic above illustrates the key imperatives required for a successful and highly efficient implementation

In today’s volatile healthcare environment, health information managers are being asked to do more with less—less staff exertion, less technology, less time, and less workspace—while providing patients, physicians, nurses, and administrators with a high level of service. To meet increasing demands, HIM professionals can join their healthcare colleagues in looking to lean thinking, a philosophy of management that focuses on process improvement and change management.

Lean thinking can be used to identify and eliminate waste in any activity performed within a facility. Based on the Toyota model, lean thinking focuses on how efficiently resources are being used, and with each step in a given process stops to ask “what value is being produced?” The method can be used to improve service to any group within a facility, including eliminating processes that offer no value to healthcare’s ultimate customer: the patient.

Recently when running this 2 day workshop at Birmingham Women’s Hospital – the team completed a Value Stream Map of their Patient Outpatients – Patient Journey and identified 25% in efficiency savings and also 8 Areas of Waste which they have now created Lean project Teams to address.